Research

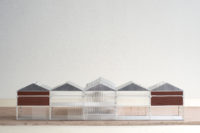

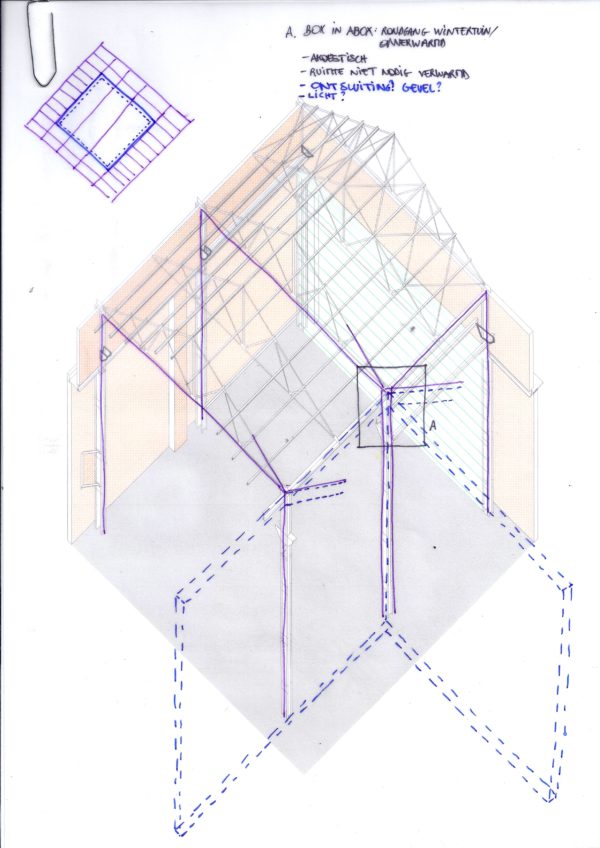

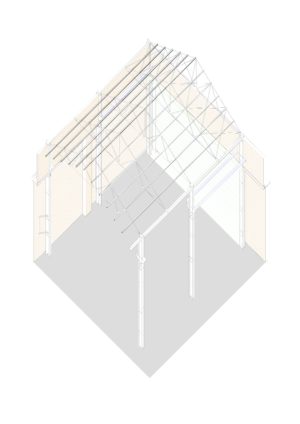

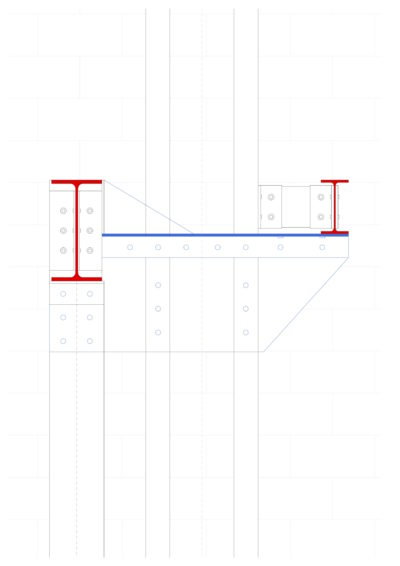

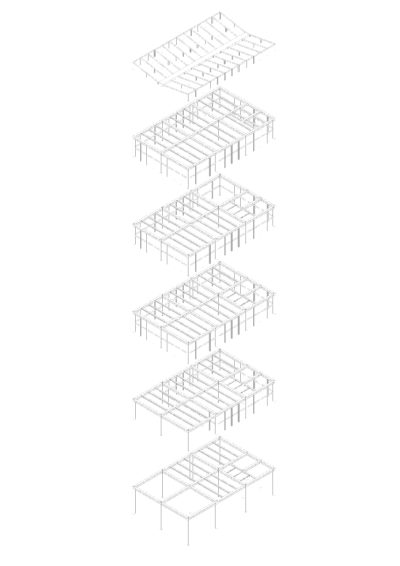

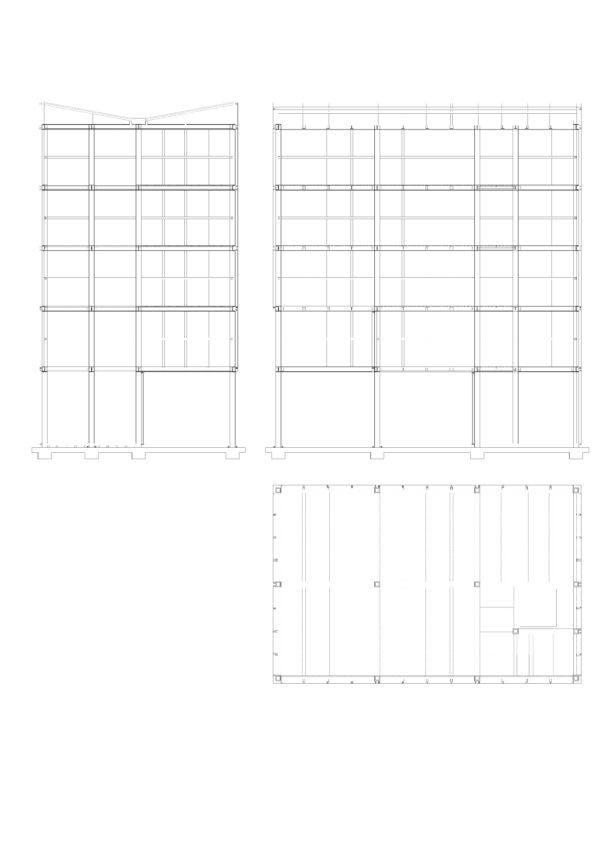

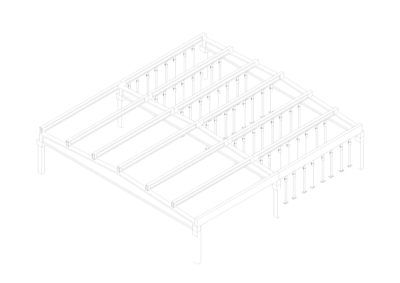

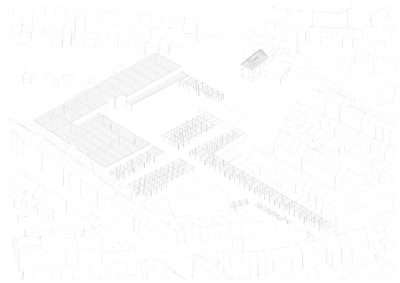

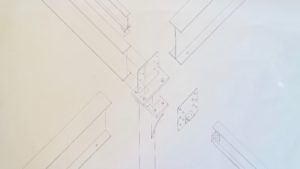

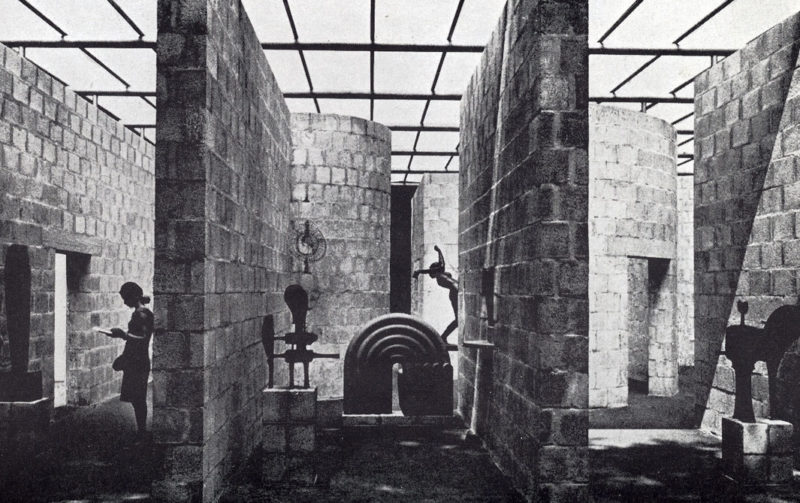

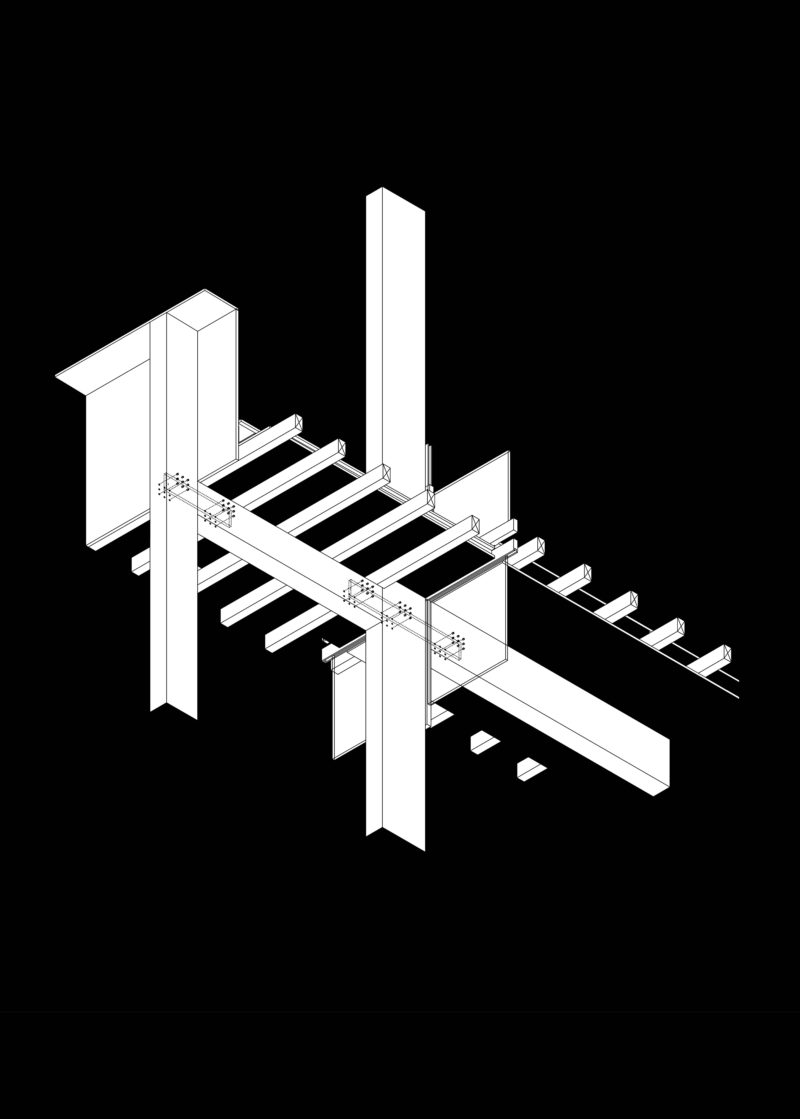

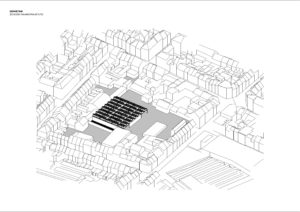

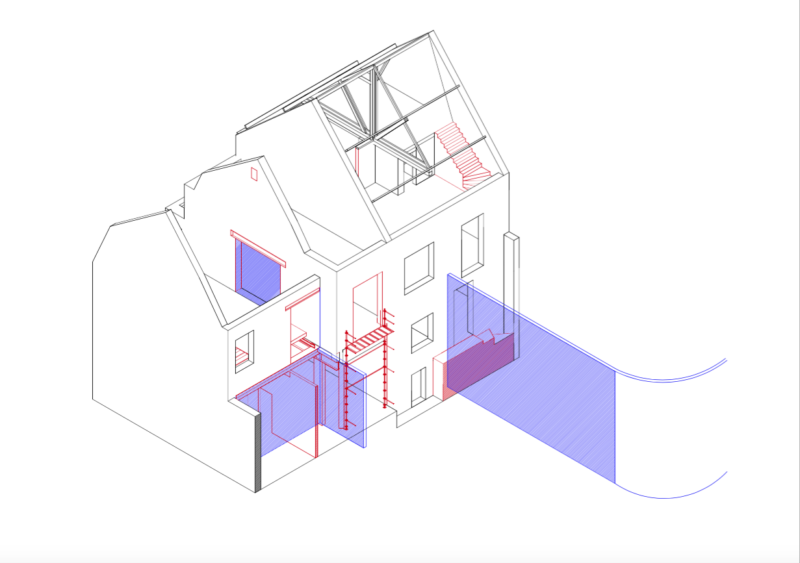

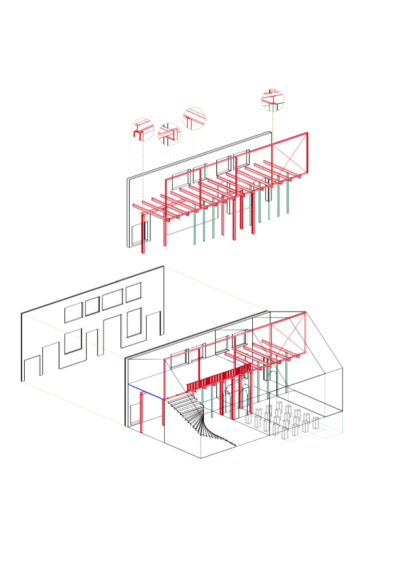

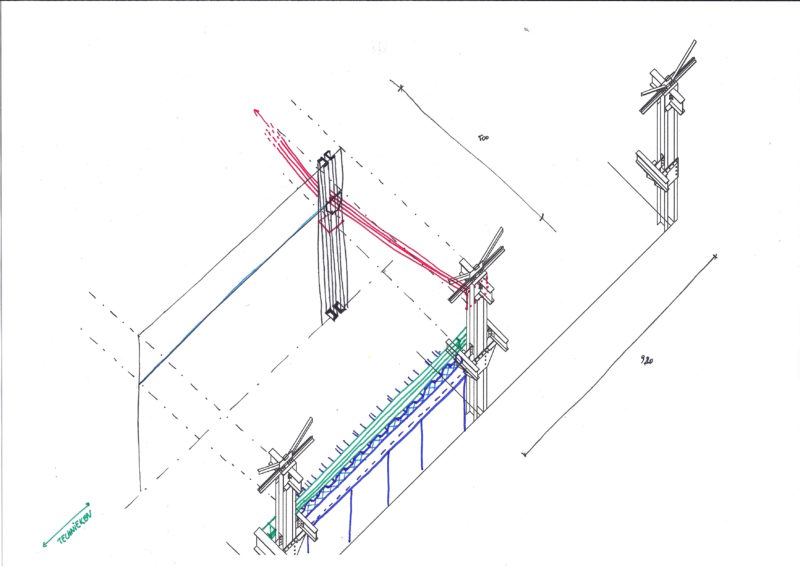

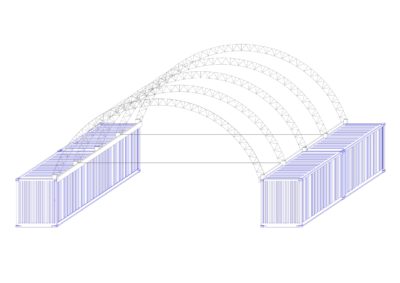

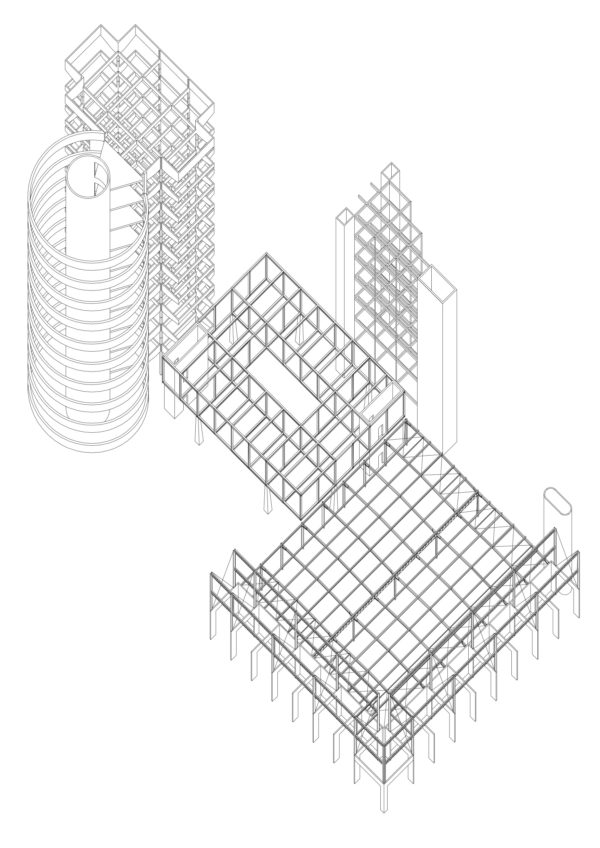

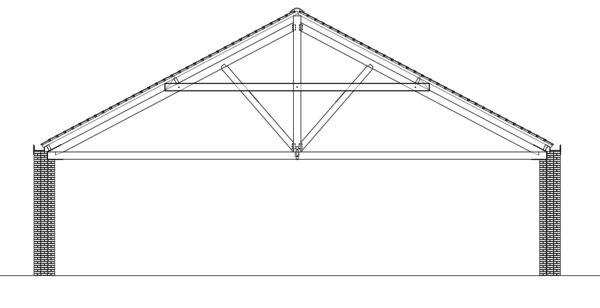

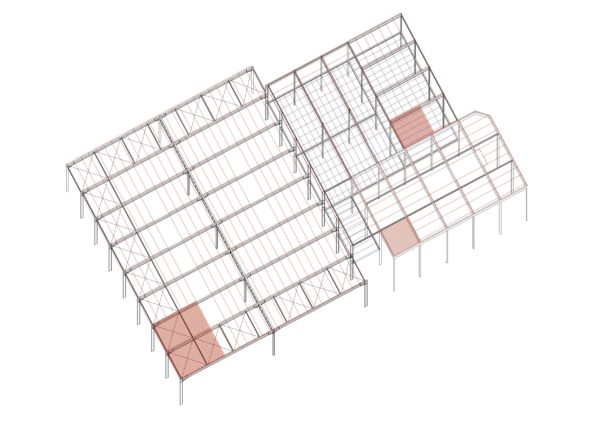

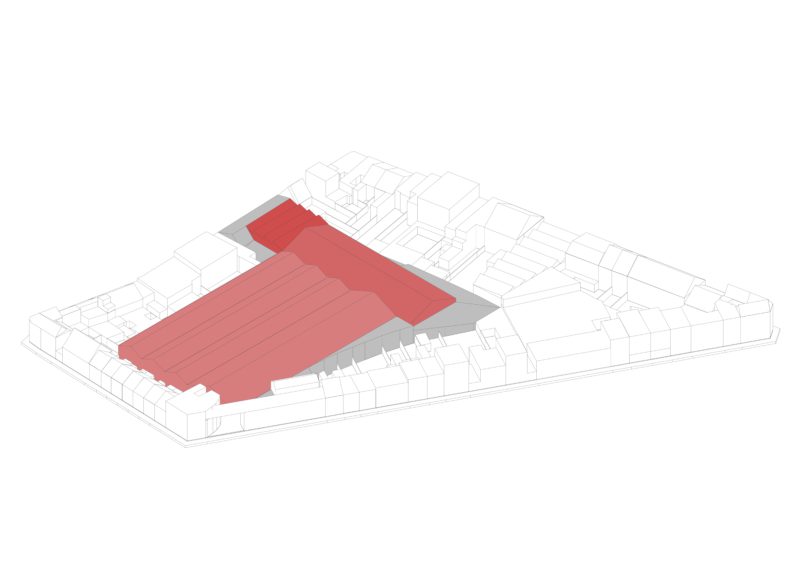

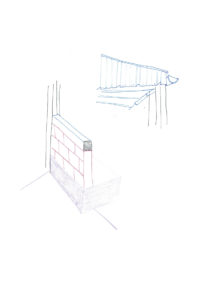

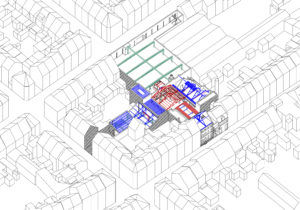

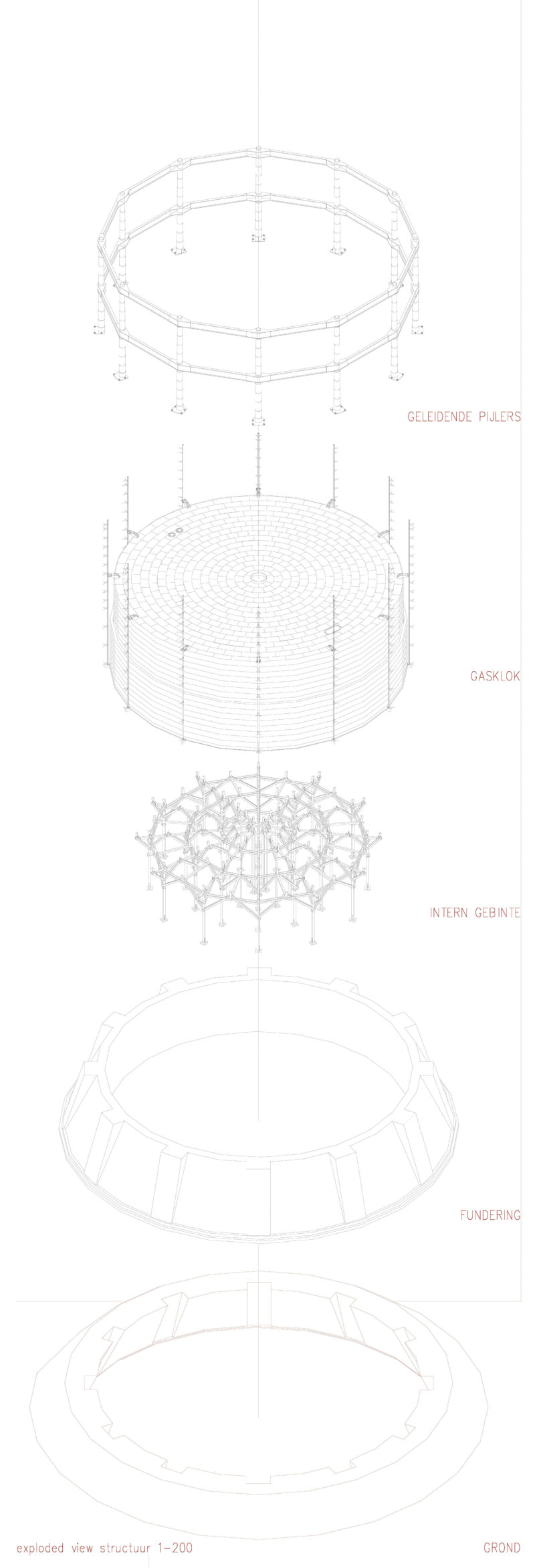

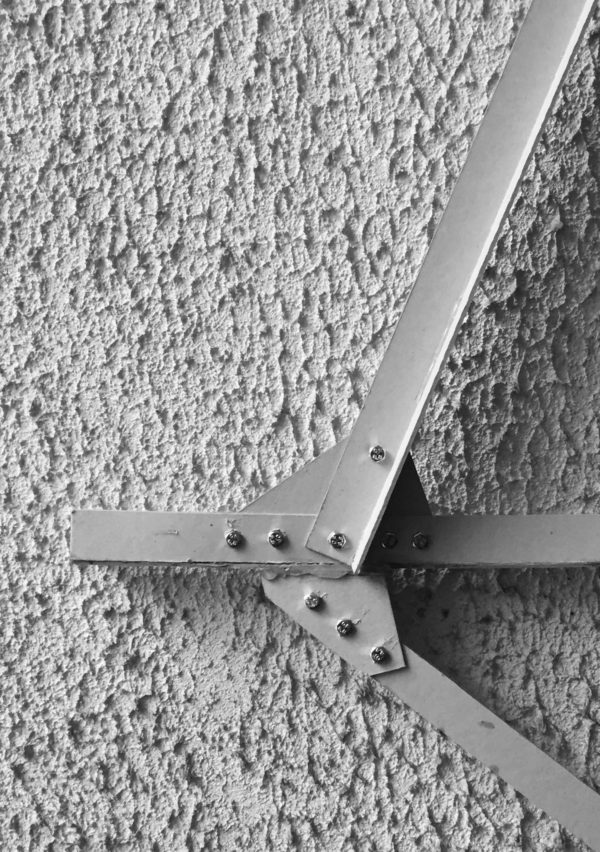

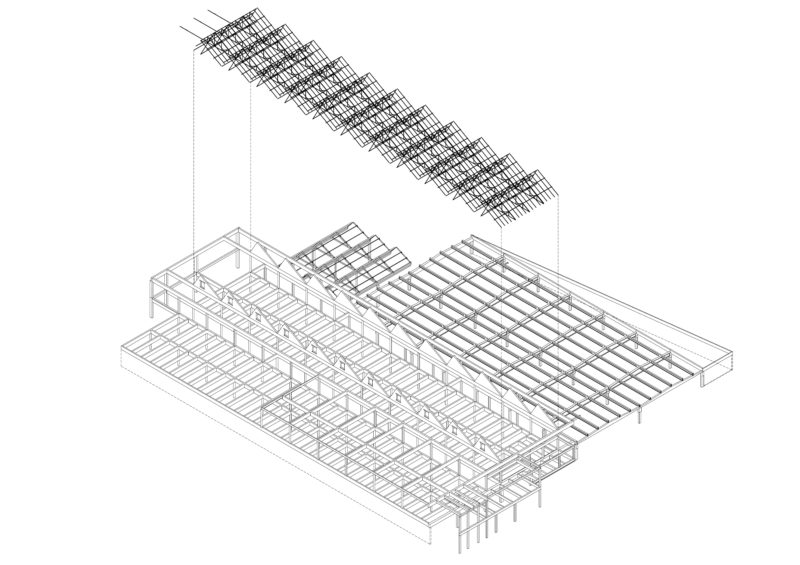

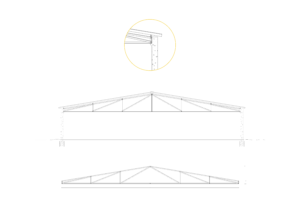

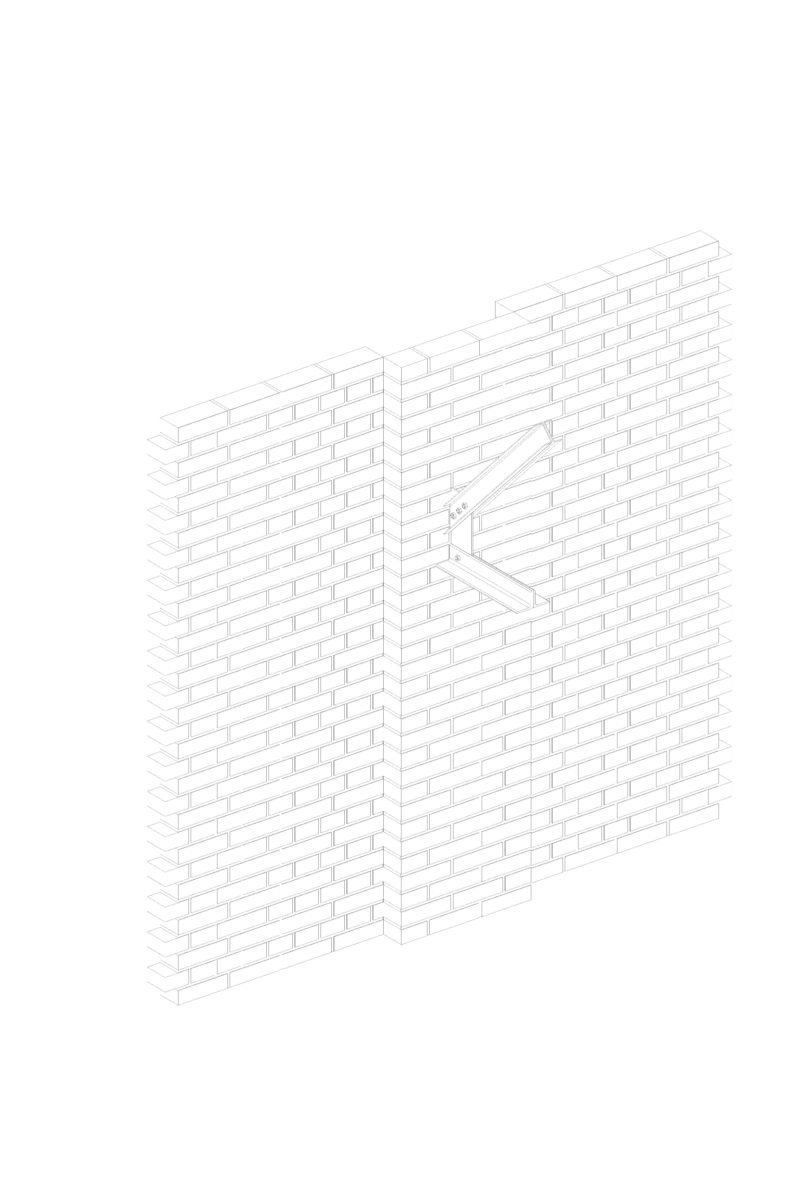

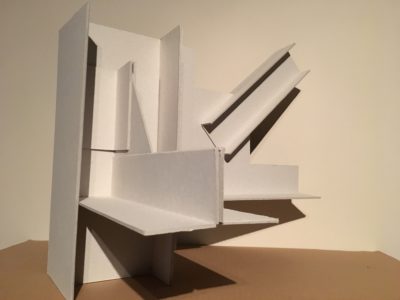

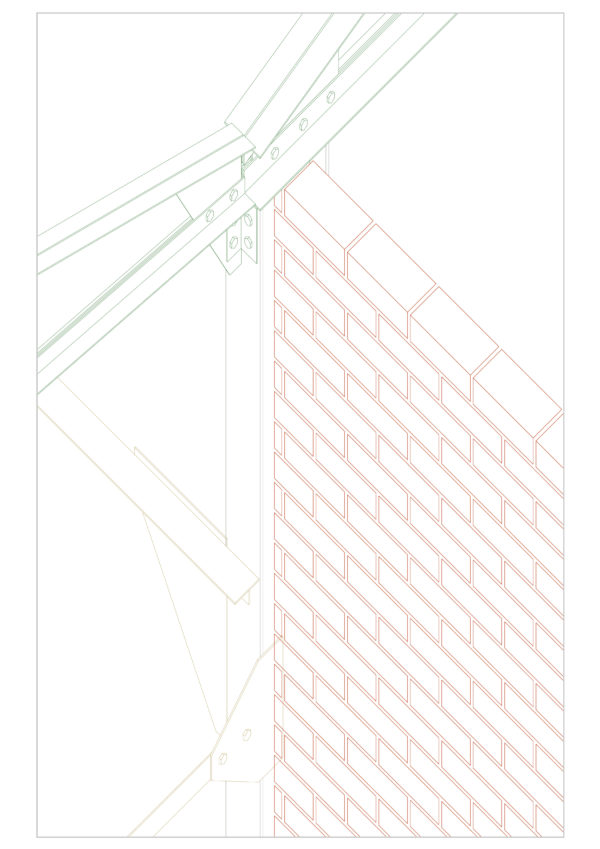

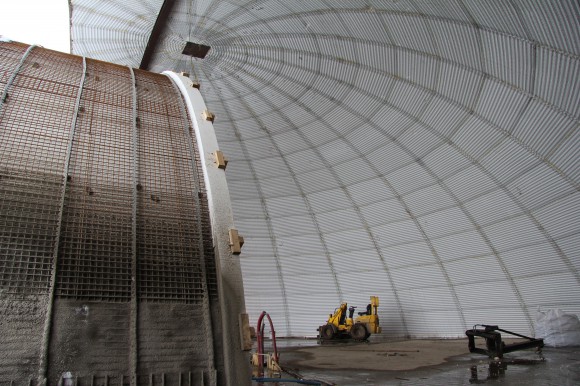

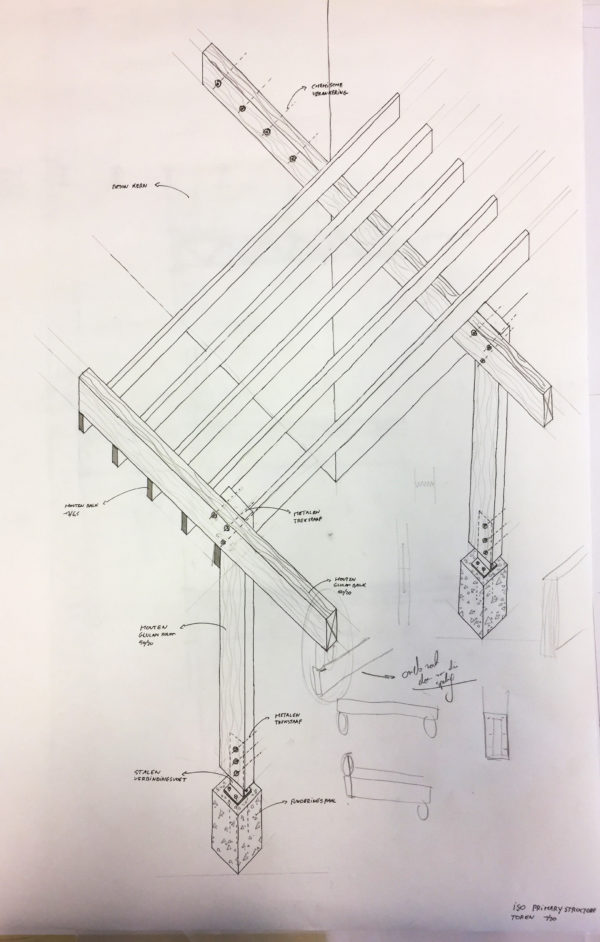

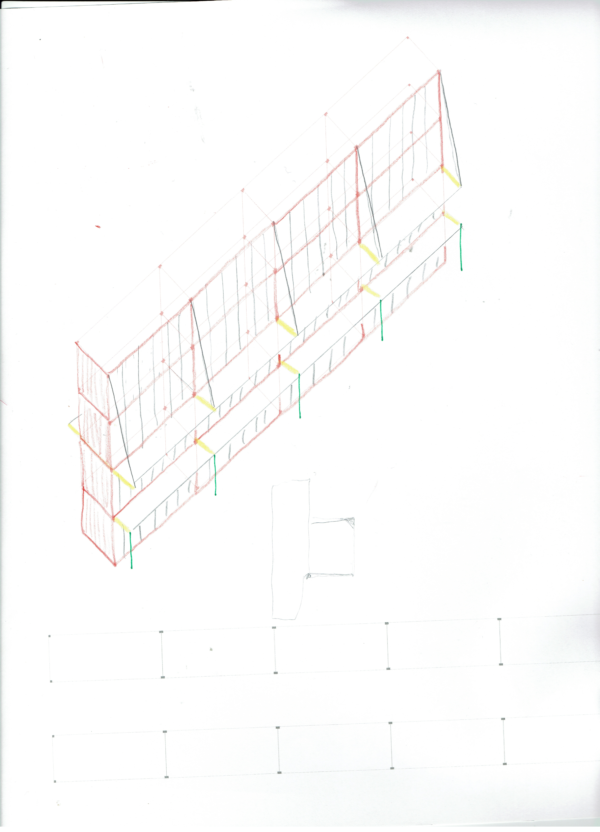

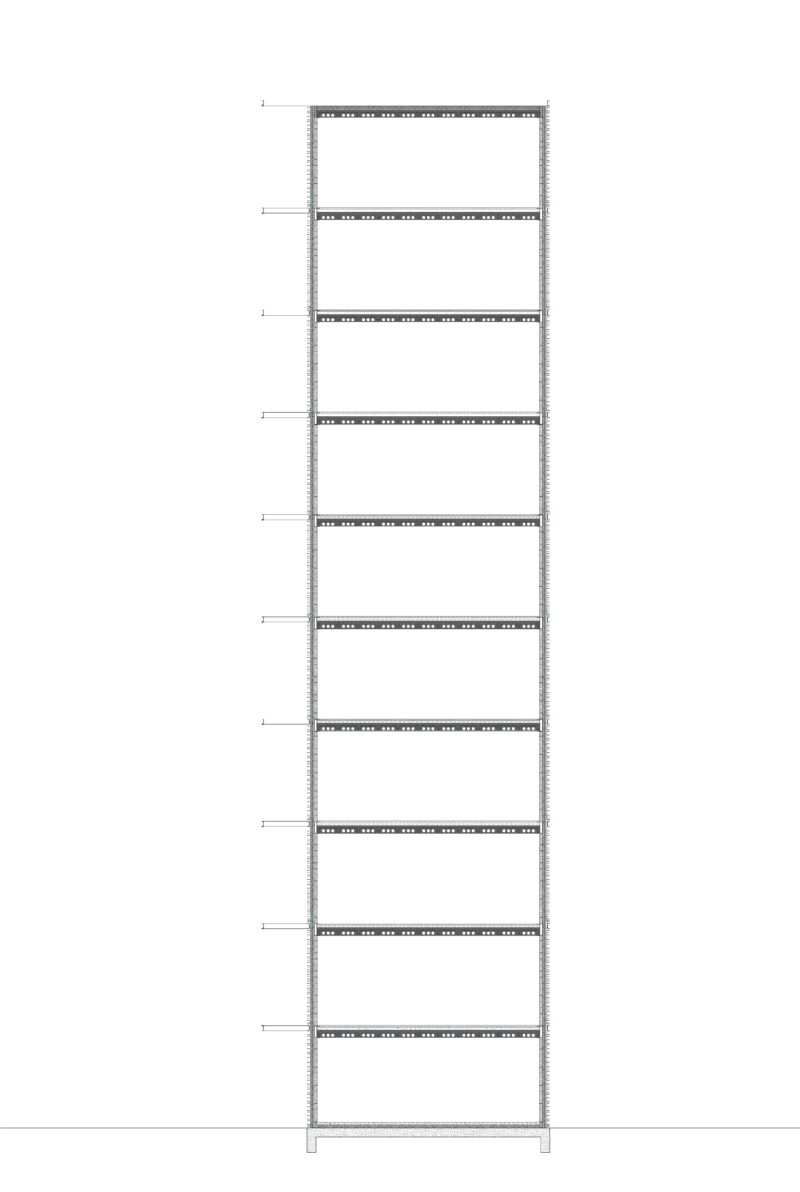

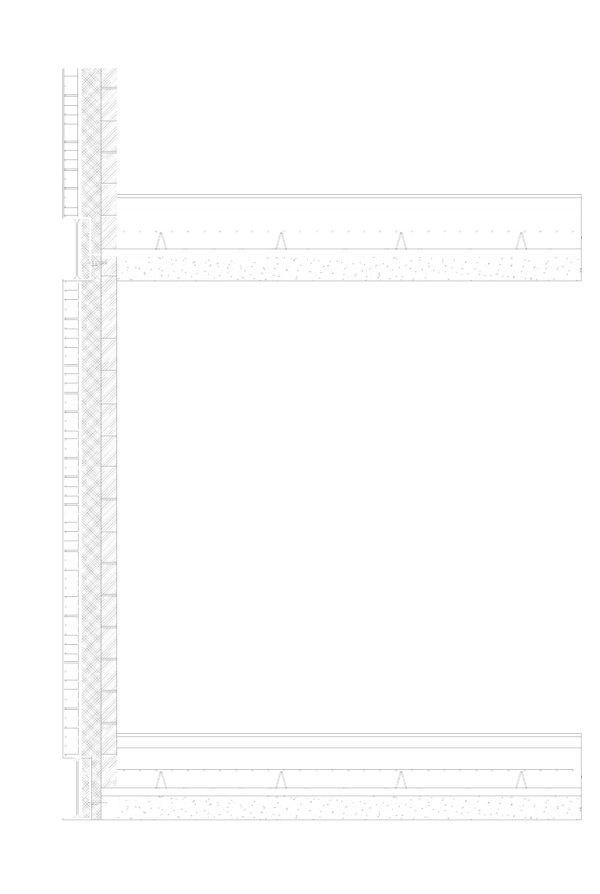

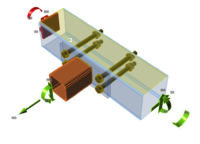

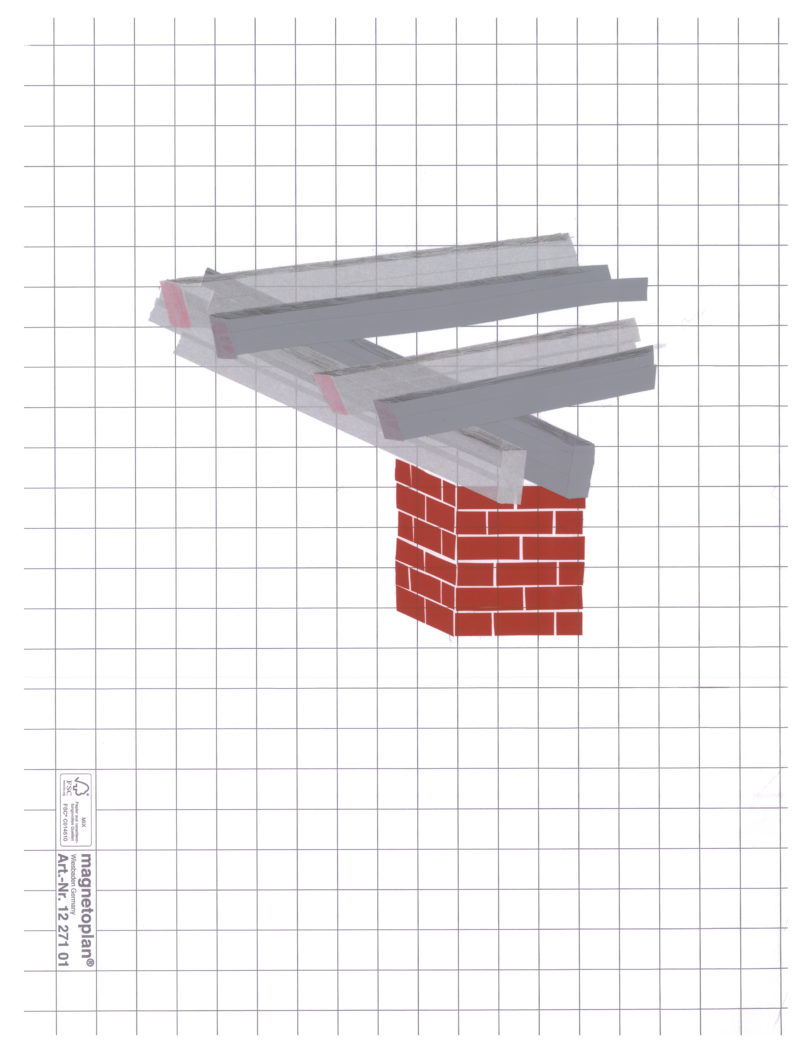

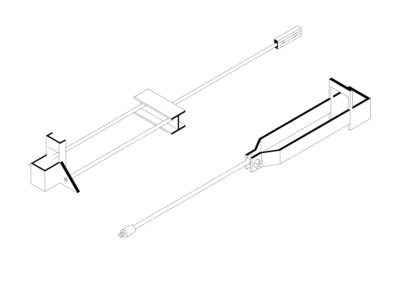

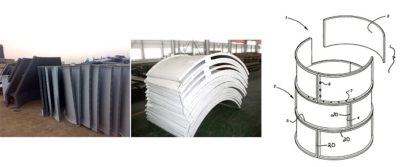

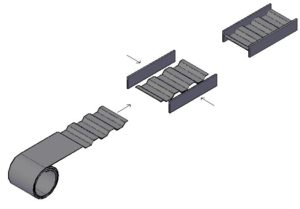

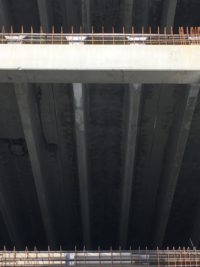

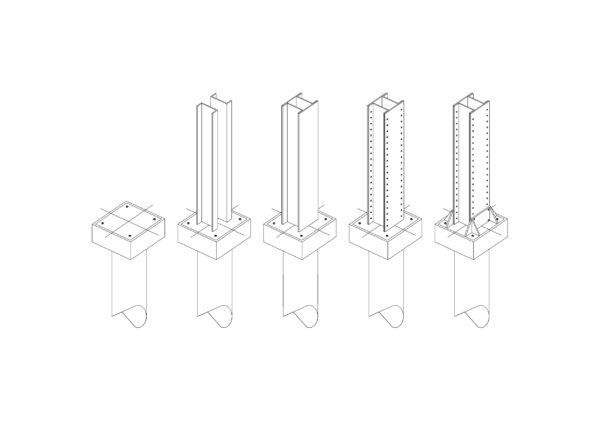

fig 4A, Hidden interior structure of the Tondelier sasholders, Interior of the Tondelier gasholders.

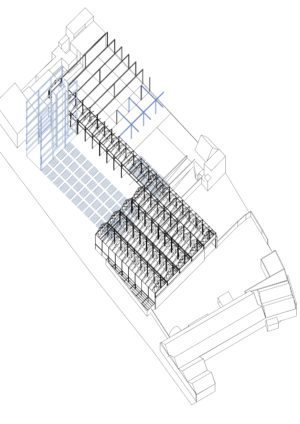

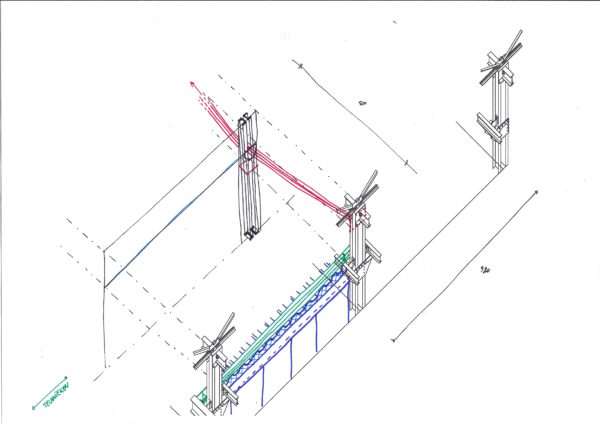

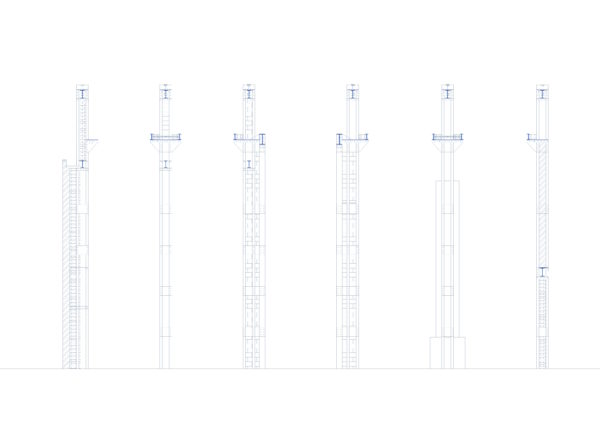

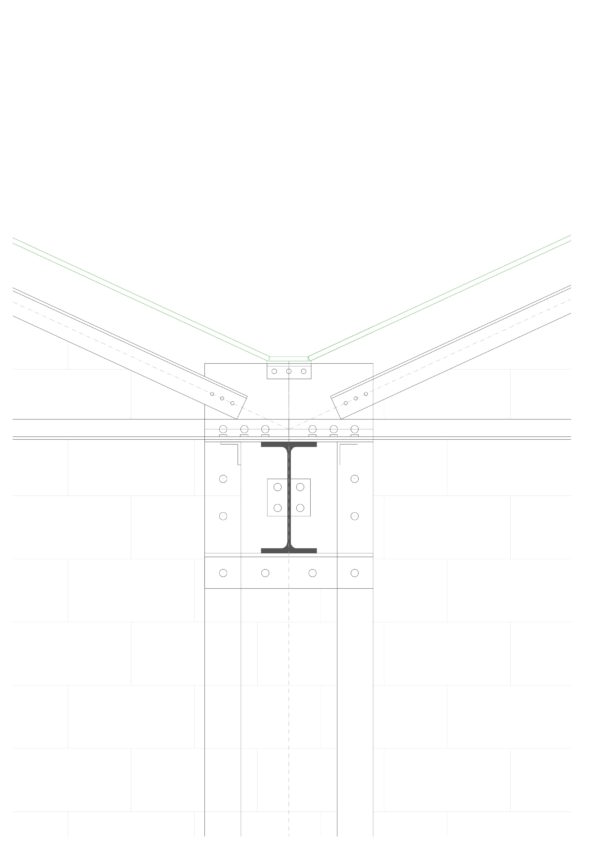

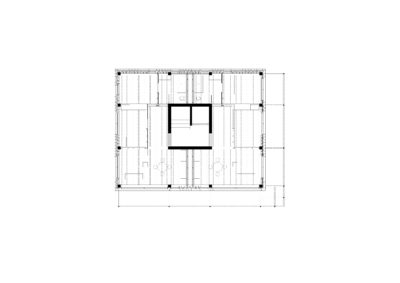

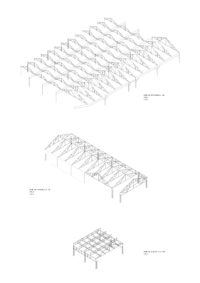

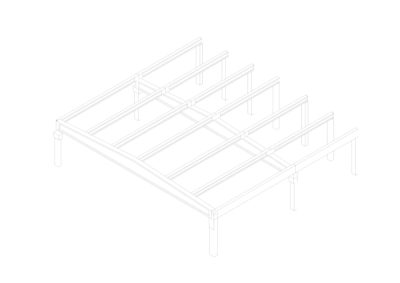

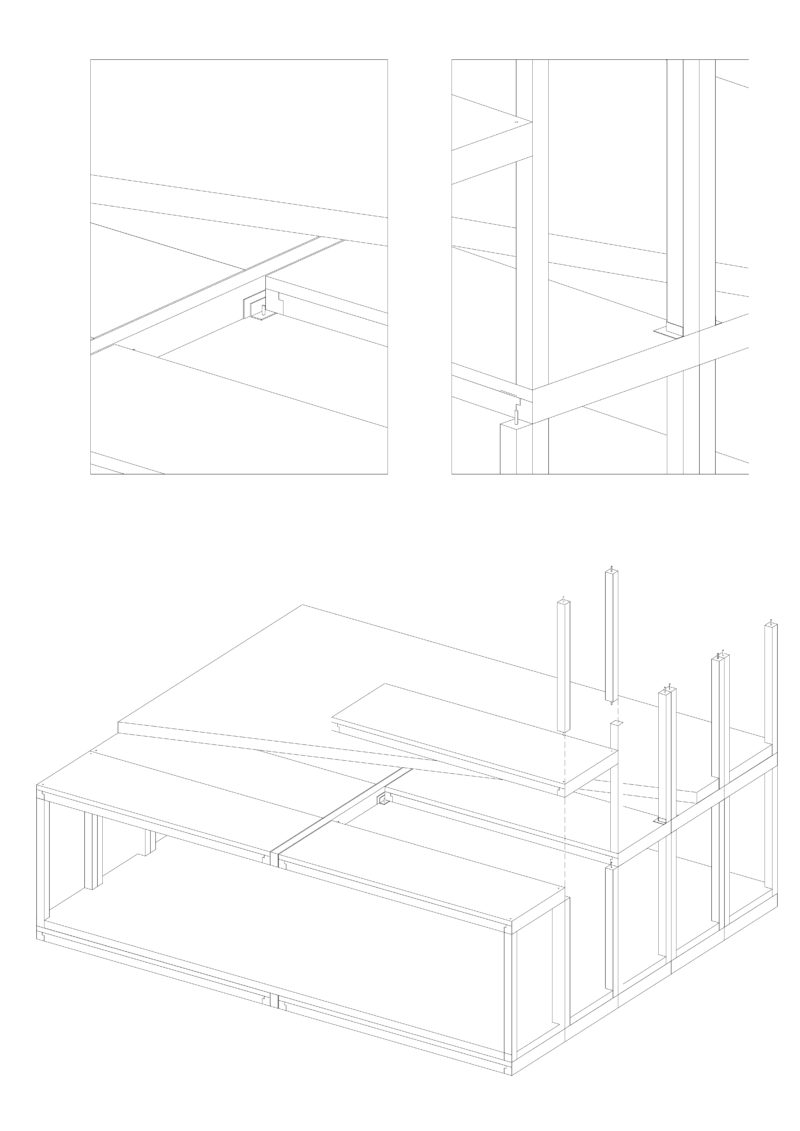

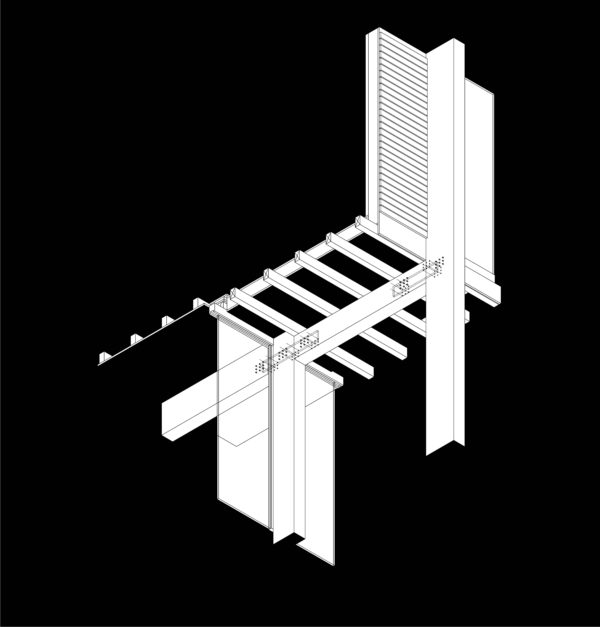

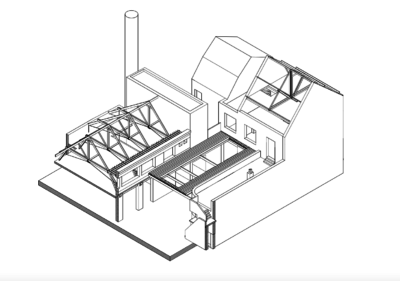

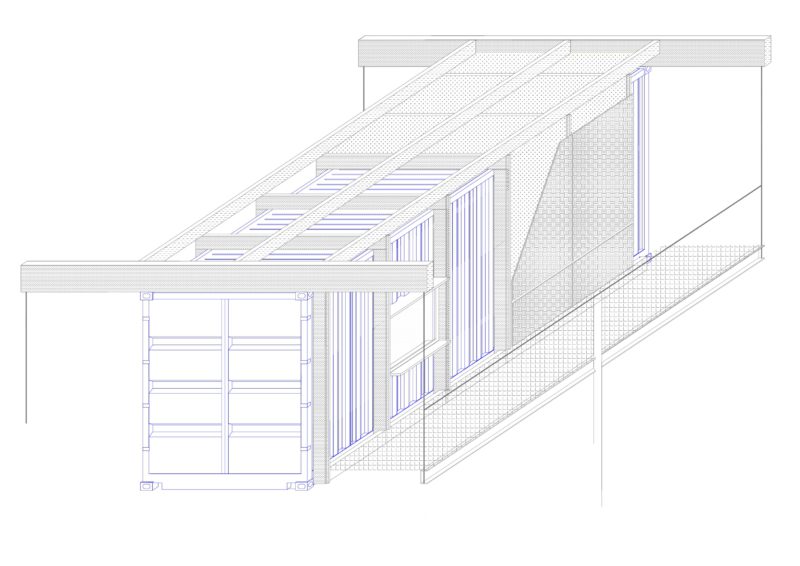

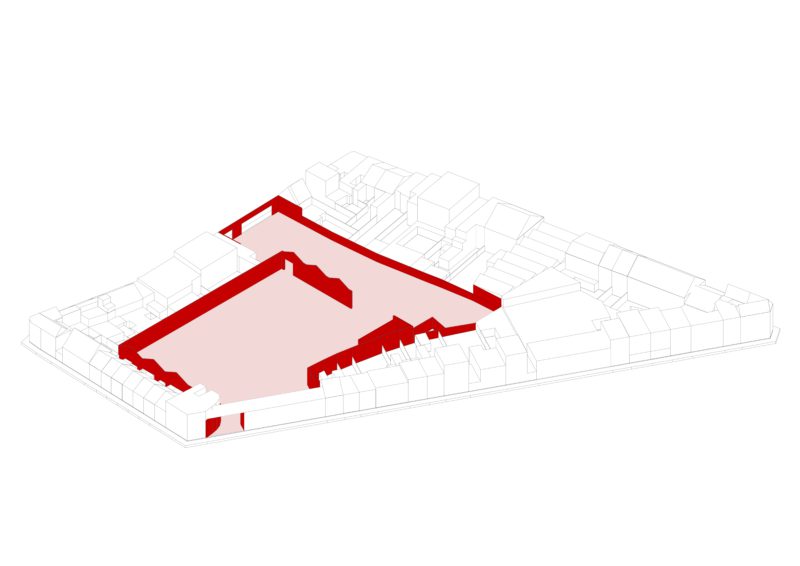

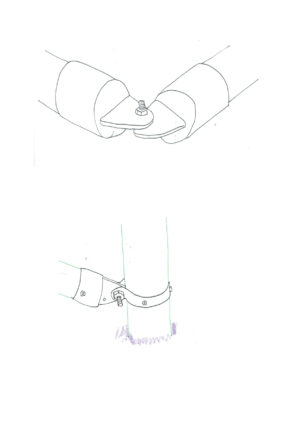

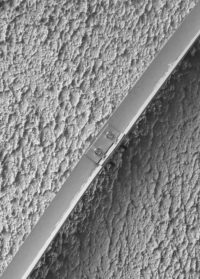

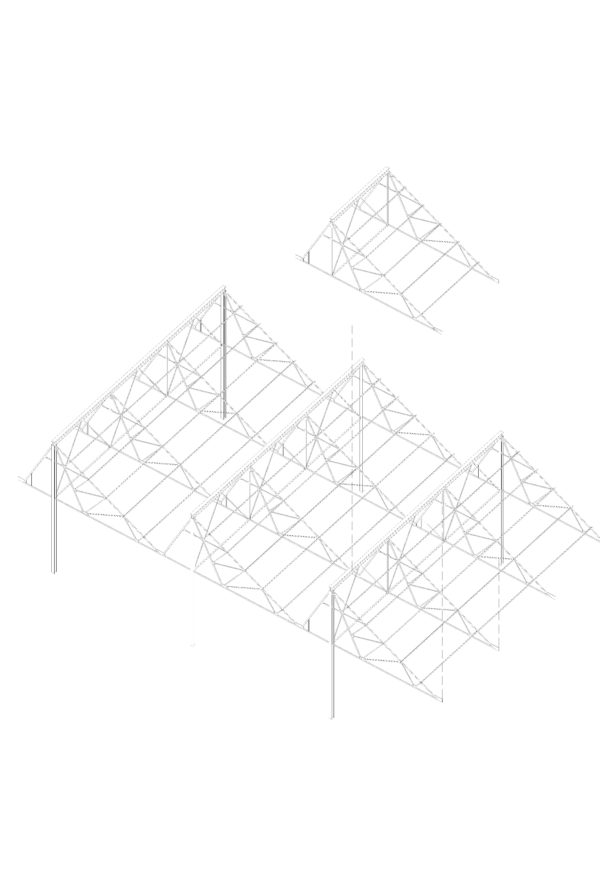

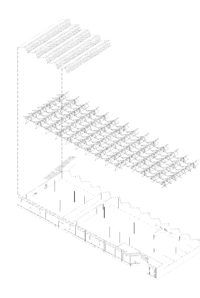

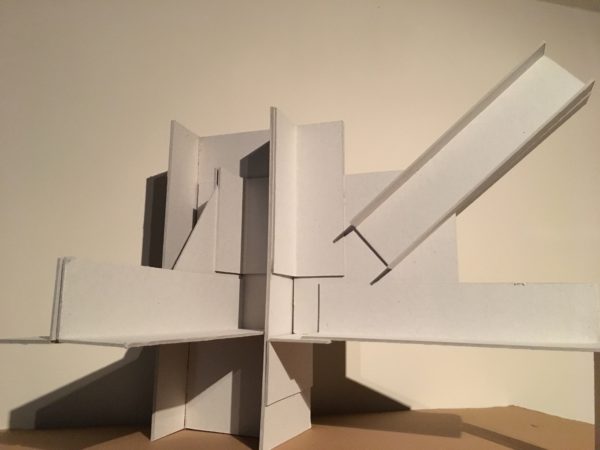

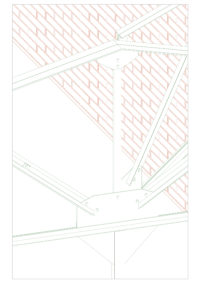

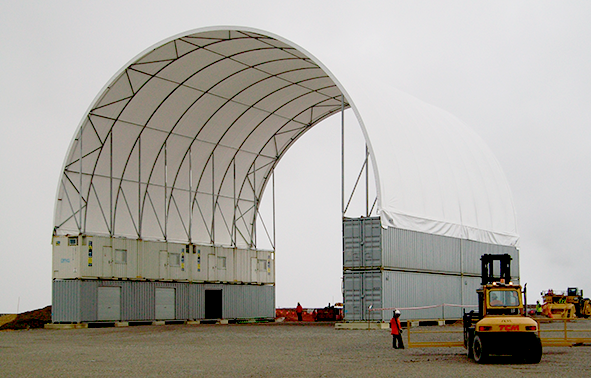

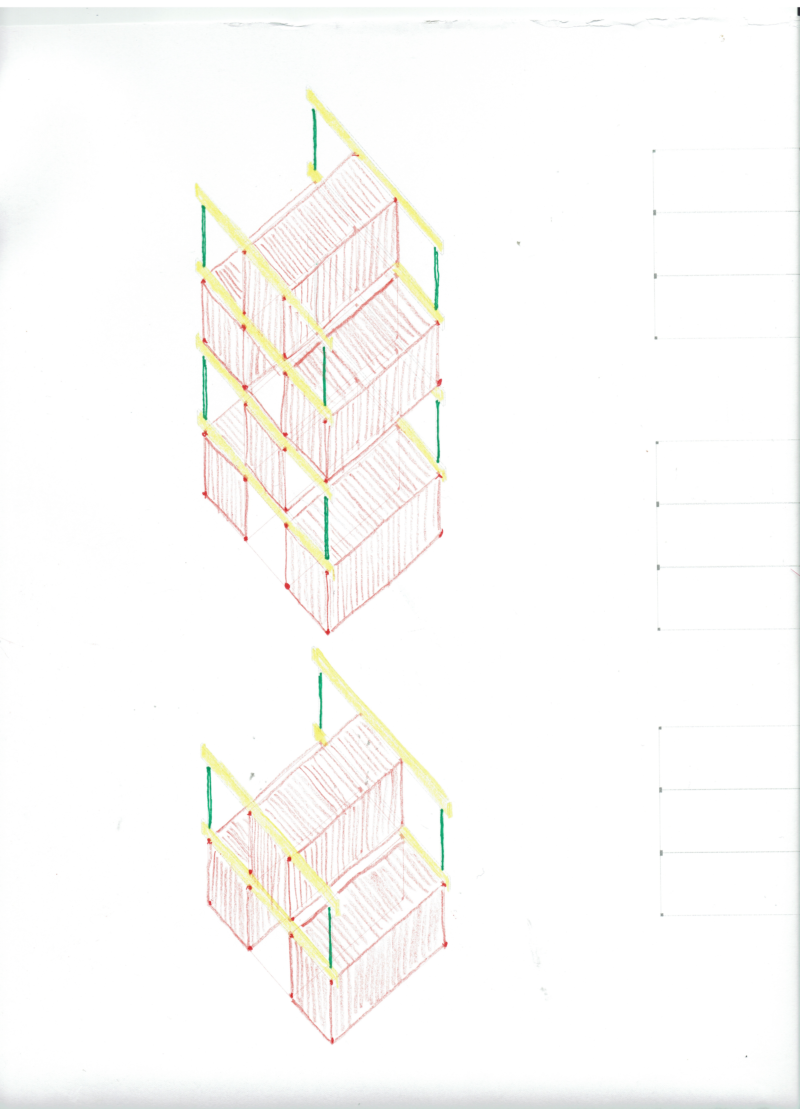

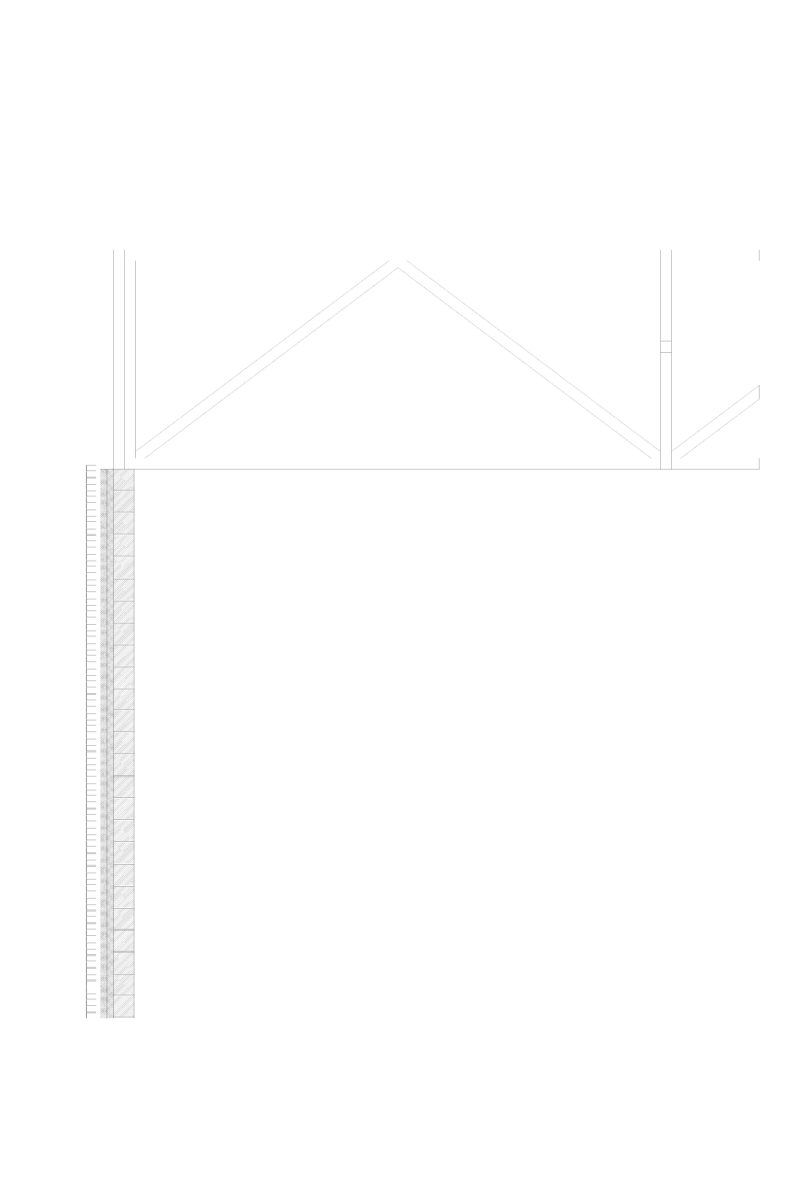

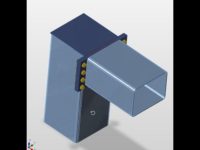

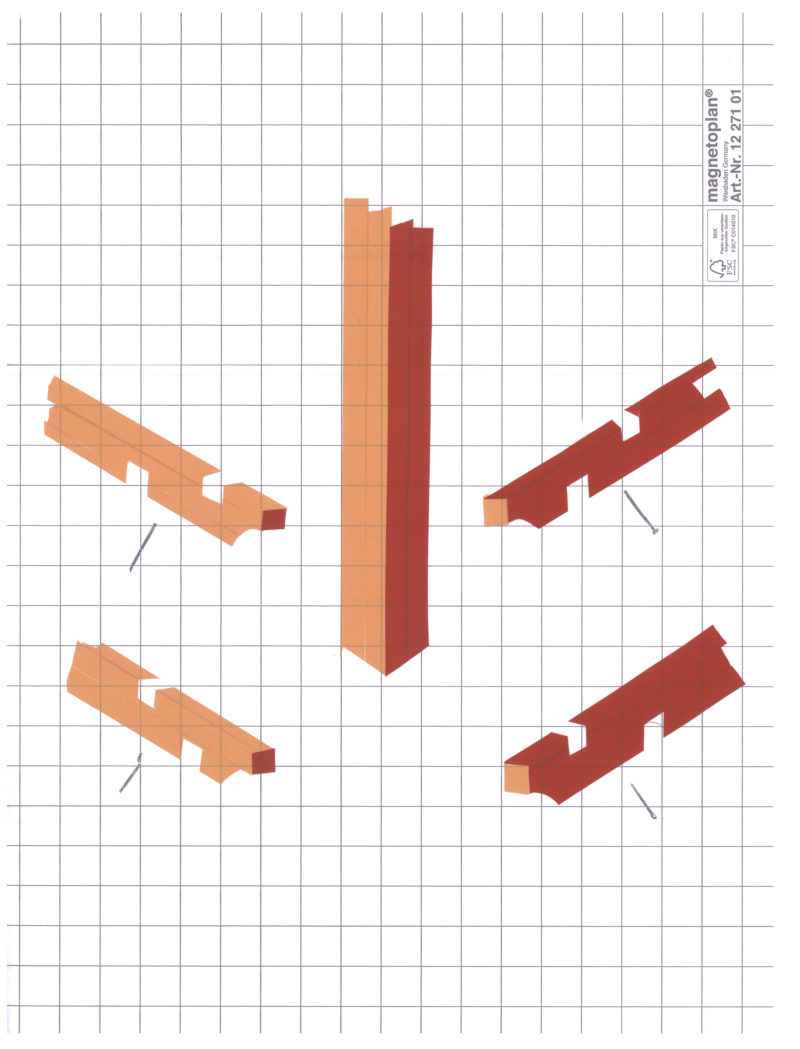

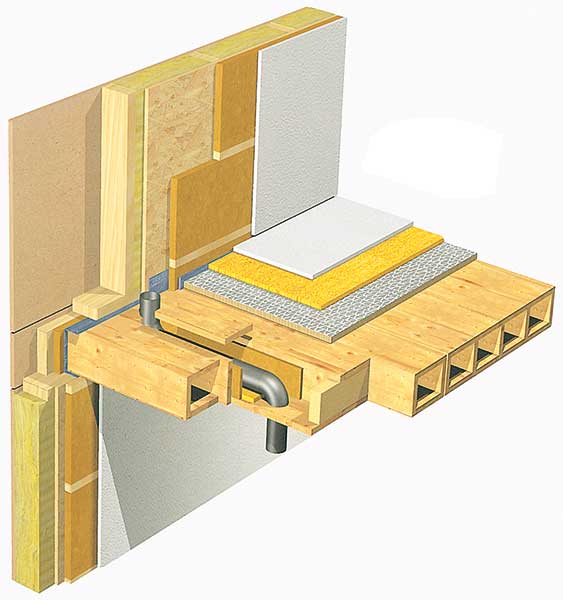

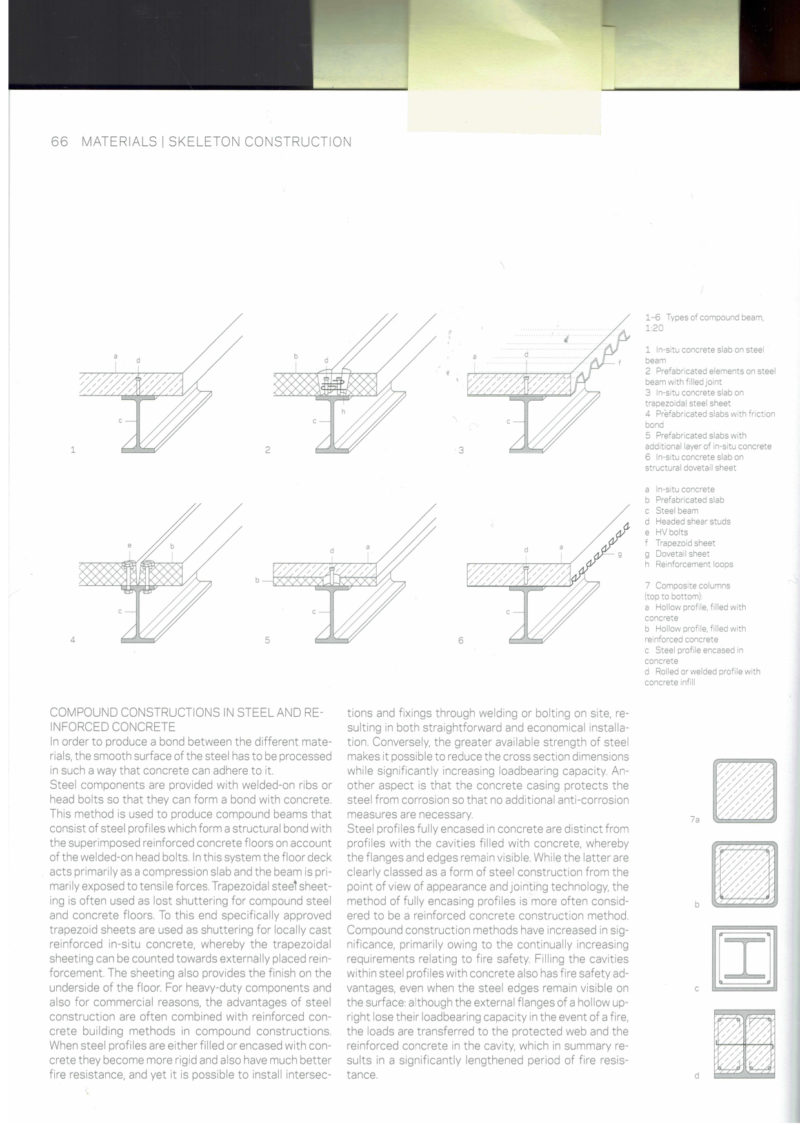

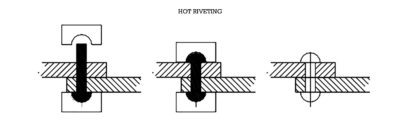

fig 4B, Hidden interior structure of the Tondelier sasholders, Interior of the Tondelier gasholders.